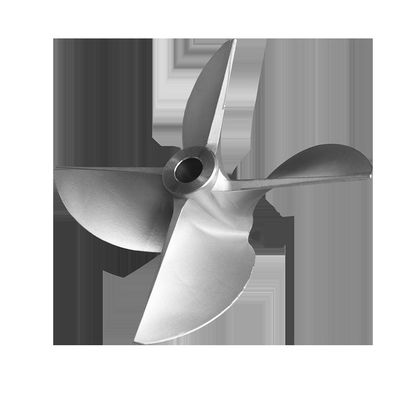

4 Balde CNC Processing Yamaha 90 Hp Propeller Outboard Engine

| Place of Origin | Shangdong |

|---|---|

| Brand Name | Liang |

| Certification | CE ISO |

| Model Number | P-04 |

| Minimum Order Quantity | 5 set |

| Price | 10 - 20 usd / set |

| Packaging Details | Standard exported packaging |

| Delivery Time | 5 -10 days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal |

| Supply Ability | 10 000 pcs every week |

| Blades | 3 | Material | 316 Stainless Steel Or Customized |

|---|---|---|---|

| Product Name | Boat Yacht Outboard Propeller | Size | Customized Size |

| Surface Treatment | Mirror Polished | Diameter (mm) | Various |

| Process | Casting, | ||

| High Light | yamaha 90 hp propeller,90 hp yamaha oem propellers,CNC yamaha oem propellers |

||

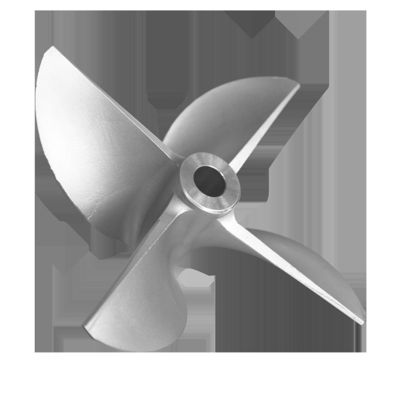

4 Balde Yamaha Outboard Engine Stainless Steel Yacht Sliver Boat Outboard Propeller

![]()

| Material | 304/316 stainless steel or customized |

| Services | Casting, Machining, Surface Treatment, Packing |

| Size and design | As the customer's drawings,requirements or samples |

| Processing | Precision investment casting and CNC machining |

| Equipments | CNC Machining Center, Boring Machine, Milling Machine, Lathe, And Radial Drilling Machine |

| Surface treatment | Mirror Polishing |

![]()

Qingdao Gold shark Marine Machinery Co., LTD is an integrated marine technology company that presently specializes in product design, production, and sales.Our company is administered by the marine equipment production systems. Every factory that our partner with has passed the CCS, ABS, DNV, LR, NK, RINA, ISO9002, TS16949, UL and other related systems authentication.

More than 10 years of accumulated experience, high-quality products, coupled with our philosophy of absolute integrity in all business dealings have earned us unanimous praise from old and new clients alike, as well as a distinctive reputation in the industry.

![]()

Our products have sold to regions as far away as Europe, North America and Asia, among others. We regularly introduce the most advanced foreign products and technologies into the domestic market and routinely share the latest in scientific and technological advancements with related domestic industries, thus providing a platform of speed and convenience From our beginnings as an international trade business model to an integrated technology solutions business model, JUVI Company has grown and transformed

itself to better serve the needs of our customers.

![]()

Q1.What material do you have?

A:SS304/SS316/SS316/Duplex 2205/ Carbon steel/Alloy steel/Aluminum.

Q2.Can you provide sample for us?

A:Yes, free sample is available;

Q3. How do you ensure quality control?

A:we ensure the quality control by 2 steps:

1)after finish, our workers will check it one by one.

2)our package department will check before they pack.

Q4. Can you do the full set project products for us?

A:Yes we can, our engineer will check your project drawings to make sure its accuracy for each different fittings and quantity.

Q5. How about your delivery time ?

A:15-20 days for glass fittings. 25-30 days for OEM fittings .

Q6.Can you do the any metal products according to our design?

A:Yes, but the drawing or sample is needed.

Q7.What surface treatment for the products your factory can offer?

A:Mirror, Chrome, Satin, Brushed ,Power coated, Electrolytic polishing.

Q8. OEM and ODM ?

A: Yes. Warmly welcomed!

Q9. Do you have any MOQ limit for order?

A: Low MOQ, 1pc for sample checking is available.

![]()

Our company has strong R&D capability and develops many new products every year. In production, we strictly follow the ISO 9001 quality system to control quality and arrange production:

1. Don’t accept defective, strict inspection of supplier's raw materials.

2. Don’t manufacture defective, the production process are strictly controlled. For all products, the workers are strictly self-inspected on each machining process, and the quality inspectors do regular inspection and spot inspection.

3. Don’t transferring defective, the defective products found in the previous process shall never be allowed to be transferred to the next process. Before shipment, the finished products shall be inspected again, and if any quality problems be found, and the products shall be reworked or rejected according to the relevant requirement.

![]()